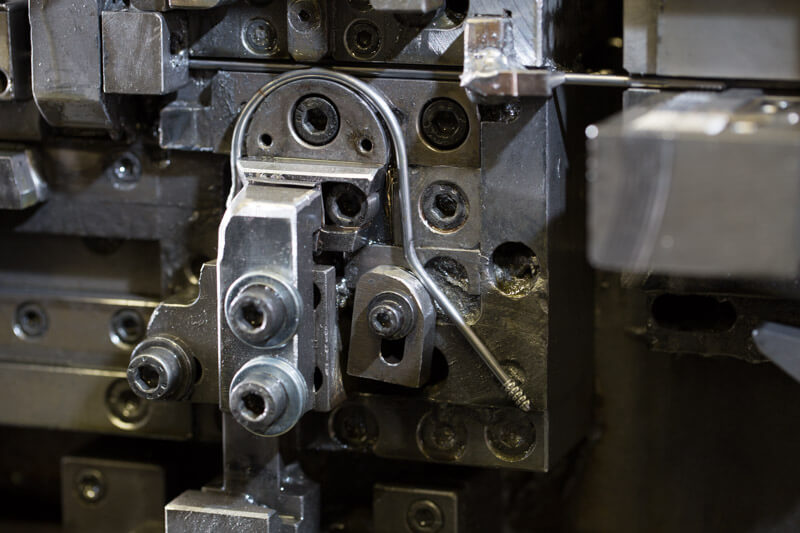

The processing of the metal wire and metal tape is divided into several phases, one of which is the bending of the metal wire and the metal tape itself. The material, collected in reels of various sizes, is put into the machine and is bent to assume the desired shape and appearance. The bending is accompanied by the possible stamping of details and the cut, the cutting of the wire or tape, operations that can take place before or after the bending process. These procedures are managed by the machine within tight time-scales, even less than a second, guaranteeing very high production volumes. It should be noted that bending can take place in different directions, so not only in width and height (two dimensions) but also in-depth (three dimensions).

A result assured by the availability of advanced machinery, able to manage any graphic project without creative limits. Capabilities that have enabled us at Cegalin to develop a complete offer for any sector, from boating to agricultural, from construction to interior design, from industry to production of household appliances. Today our company exports worldwide every year worldwide of parts and elements realised through the bending of metal wire and metal tape, using top quality iron and steel as the starting material.

FROM THE IDEA TO THE BENDING OF THE TAPE AND WIRE

The decades of experience of Cegalin Srl has led us to be very competitive both in terms of the price of our services and in terms of timing. From the moment the customer contacts us to the moment we start the work only a few days pass, sometimes less than 48 hours. A speed guaranteed by the availability of more than 90 machines for bending and performing the other processing of metal wire and metal tape in two and three dimensions. Contacting us means relying on a reliable and competent partner, ready to respond to any request with the professionalism that has always distinguished us.

Put us to the test!